-

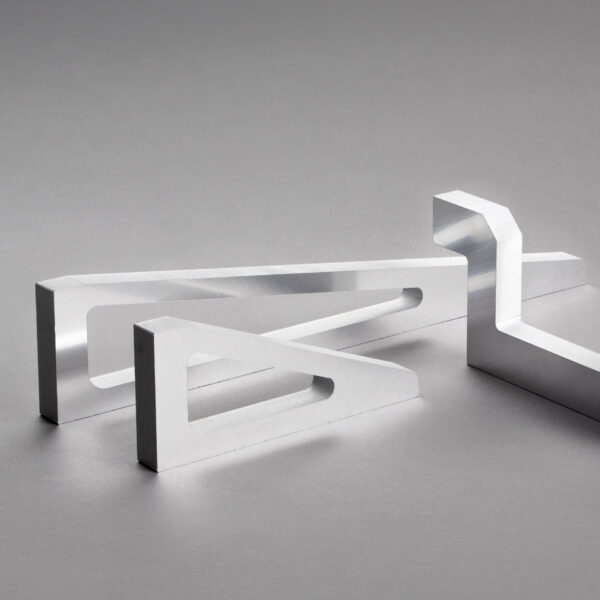

What we can cut by water jet

We can apply waterjet cutting to basically any material with the exception of tempered glass and substances that react violently with water.

-

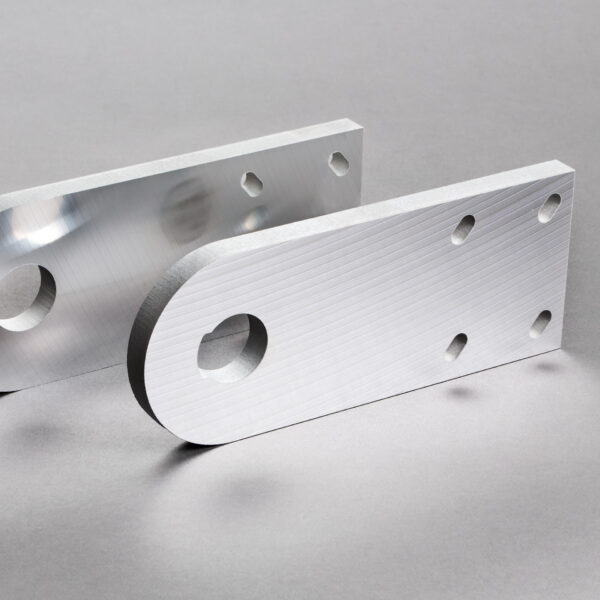

Maximum cutting dimensions and weight of input material

The highest possible weight of the input material is 5000 kg total and 1000 kg/m2. The dimensions of the cutting surface are 3000 x 5000 mm. The maximum width of the material that can be cut is 320 mm.

Waterjet cutting

…since 2006. The capacities and possibilities of our operation were later expanded via the purchase of a high-pressure waterjet with a cutting head equipped with a tilting function, which allows for the elimination of chamfers that commonly occur during

Do you have a question about the product?

Ask us

Please fill out the form and submit. We will contact you.

-

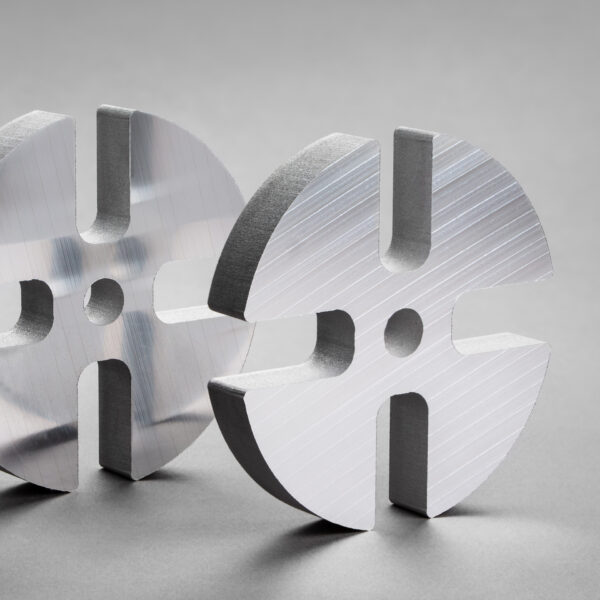

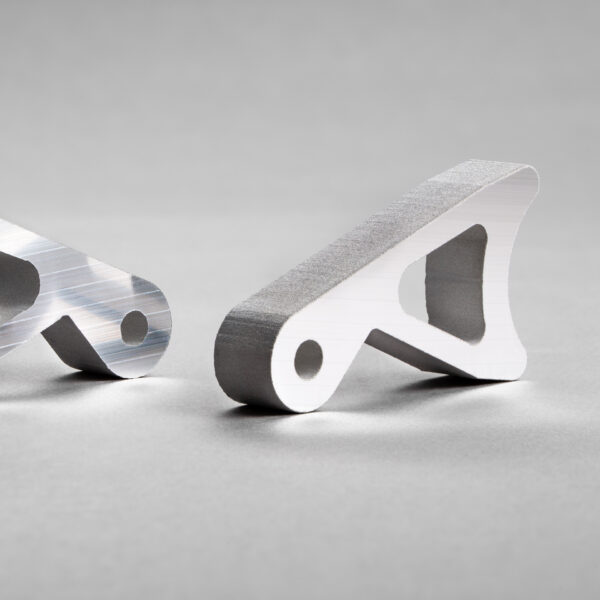

Specification of shape cut by water jet

Maximum quality – Used primarily in cases where the customer does not want to process the material or wants to process it only to a minimal degree. We recommend using this cutting up to a width of 50 mm. Here we commonly guarantee an accuracy of +/- 0.3 mm. The cut surface is smooth and is reminiscent of sand blasting in structure.

Medium quality – As the name implies, this is a cut that is between the best and worst quality. This cut is visually acceptable and suitable for visible, “non-functional” parts of machines. Cut tolerance ranges from +/- 0.3 mm to +/- 1.5 mm depending on the width of the material being cut. For widths up to 30 mm, the differences between maximum and average quality are hardly visible. For widths over 30 mm, the cut surface is slightly corrugated.

Low quality – We usually use this quality in cutting semi-finished products that will be further processed. In widths over 100 mm, this cut is very coarse, and the customer can expect to receive leftover material on the edge for further processing in order to achieve a clean contour. Usually 3 to 20 mm depending on the width of the part. In this case, cut tolerance ranges from +/- 0.5 mm to +/- 15 mm again depending on the strength of the material. The cut surface is corrugated. The coarseness of corrugation increases according to the width of the material.

-

Stock assortment of cast and rolled sheets and plates, from which we perform shape cutting with a water jet

ENAW 5754 H111 up to th. 25 mm ENAW 5083 H111 up to th. 50 mm ENAW 6082 T651 up to th. 250 mm ENAW 2017A T451 up to th. 180 mm ENAW 2024 T351 up to th. 105 mm ENAW 7075 T651 up to th. 250 mm 5083 litá up to th. 250 mm

-

Production assortment of milled sheets and plates, from which we perform shape cutting with a water jet

ALQAL 5083 from th. 4 mm up to th. 100 mm ALXAL 5754 from th. 6 mm up to th. 50 mm ALCAST 7021 from th. 15 mm up to th. 50 mm ALVAL 6082 from th. 10 mm up to th. 50 mm ALVAL 7075 from th. 10 mm up to th. 30 mm

Do you have a question about the product?

Ask us